We run regular Delivery Methodology sessions for a mixture of Delivery Managers and other folk involved in running Delivery Teams. It’s the beginning of a Community of Practice around how we deliver.

One of the items that someone added to our list for discussion recently was about how we forecast effort, in order to predict delivery dates. Straight away I was thinking about how we shouldn’t necessarily be forecasting effort, as this doesn’t account for all of the time when things spend blocked, or just not being worked on.

Instead we should be trying to forecast the flow of work.

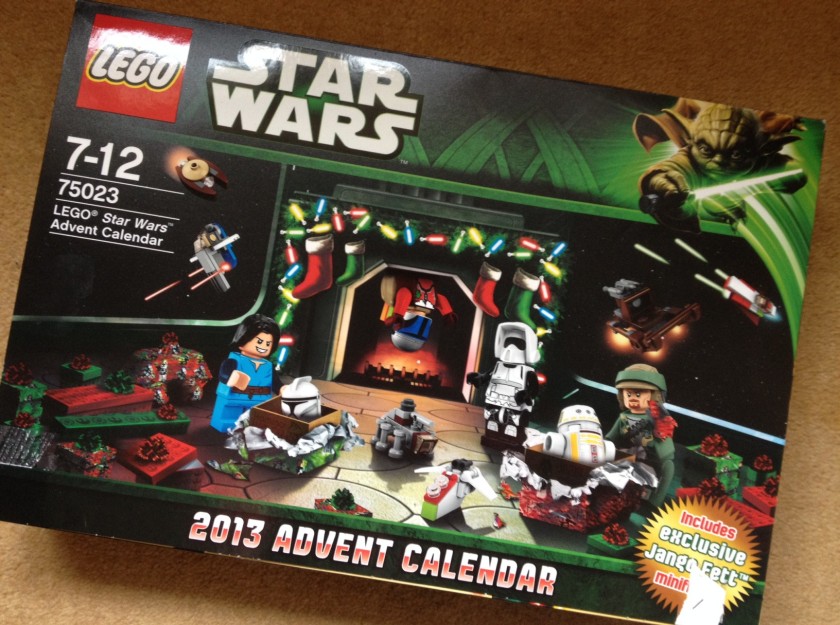

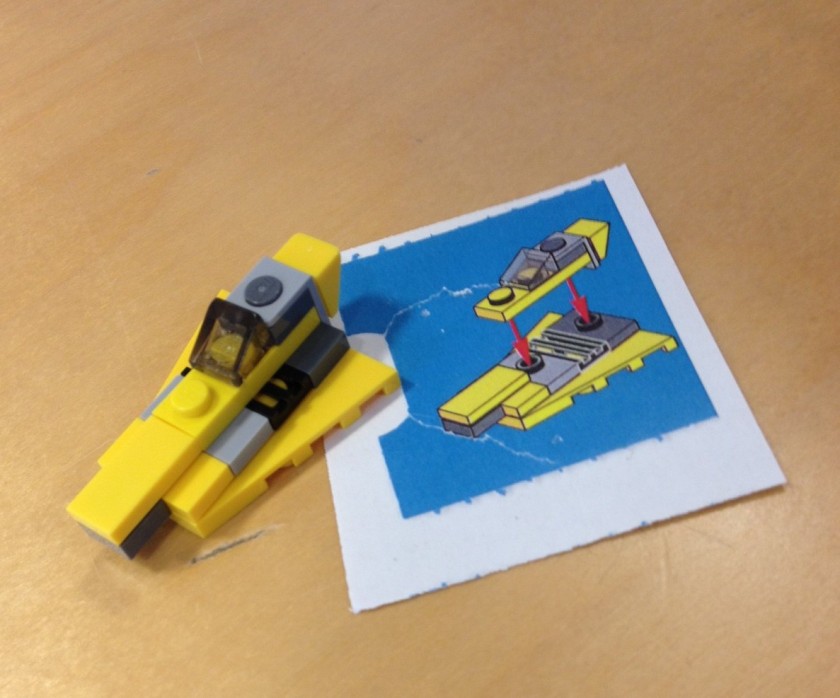

We’d been through a lot of this before, but we have bunch of new people in the teams now, and it seemed like a good idea for a refresher. My colleague Chris Cheadle had spotted the Lego Flow Game, and we were both keen to put our Lego advent calendars to good use, so we decided to run this as an introduction to the different ways in which work can be batched and managed, and the effect that might then have on how the work flows.

The Lego Flow Game was created by Karl Scotland and Sallyann Freudenberg, and you can read all of the details of how to run it on Karl’s page. It makes sense to look at how the game works before reading about how we got on.

We ran the game as described here, but Chris adapted Karl’s slides very slightly to reflect the roles and stages involved in our delivery stream, and he tweaked the analyst role slightly so they were working from a prioritised ‘programme plan’.

Round 1 – Waterfall

Maybe we’re just really bad at building Lego, but we had to extend the time slightly to deliver anything at all in this first round! Extending the deadline, to meet a fixed scope, anyone?

The reason we only got two items into test and beyond was that the wrong kits were selected during the ‘Analysis’ phase for three items. The time we spent planning and analysing these items was essentially wasted effort, as we didn’t deliver them.

The pressure of dealing with a whole batch of work at that early stage took it’s toll. This is probably a fairly accurate reflection of trying to do a big up-front analysis under lots of pressure, and then paying the price later for not getting everything right.

It was also noticeable that because of the nature of the ‘waterfall rules’, people working on the later stages of delivery were sat idle for the majority of the round – what a waste!

Our Cumulative Flow Diagram (CFD) for the Waterfall Round looked like this –

You can see how we only delivered two items, and these weren’t delivered until 7:00 – no early feedback from the market in this round!

CFDs are a really useful tool for monitoring workflow and showing progress. I tend to use a full CFD to examine the flow of work through a team and for spotting bottlenecks, and a trimmed down CFD without the intermediate stages (essentially a burn-up chart) for demonstrating and forecasting progress with the team and stakeholders.

You can read more about CFDs, and see loads of examples here.

Round 2 – Time-boxed

We did three three-minute time-boxes during this round. Before we started the first time-box we estimated we’d complete three items. We only completed one – our estimation sucked!

In the second time-box we estimated we’d deliver two items and managed to deliver two, just!

Before the third time-box we discussed some improvements and estimated that we’d deliver three again. We delivered two items – almost three!

Team members were busier in this round, as items were passed through as they were ready to be worked on.

The CFD looks a bit funny as I think we still rejected items that were incorrectly analysed (although Karl’s rules say we could pass rejected work back for improvement)

The first items were delivered after 3:00 and you can the regular delivery intervals at 6:00 and 9:00, typical of a time-boxed approach.

Round 3 – Flow

During the flow round, people retained their specialisms, but each team member was very quick to help out at other stages, in order to keep the work flowing as quickly as possible.

Initially, those working in the earlier stages took a little getting used to the idea of not building up queues, but we soon got the hang of it.

The limiting of WIP to a single item in each stage forced us to swarm onto the tricky items. Everyone was busier – it ‘felt faster’.

We’ve had some success with this in our actual delivery teams – the idea of Developers helping out with testing, in order to keep queue sizes down – but I must admit it’s sometimes tricky to get an entire team into the mindset of working outside their specialisms, ‘for the good of the flow’.

Here’s the CFD –

The total items delivered was 7, which blows away the other rounds.

You can see we were delivering items into production as early as 2:00 into the round. So not only did we deliver more in total, but we got products to market much earlier. This is so useful in real life as we can be getting early feedback, which helps us to build even better products and services.

The fastest cycle time for an individual item was 2:00

A caveat

Delivering faster in the final round could be partly down to learning and practice – I know I was getting more familiar with building some of the Lego kits.

With this in mind, it would be interesting to run the session with a group who haven’t done it before, but doing the rounds in reverse order. Or maybe have multiple groups doing the rounds in different orders.

What else did we learn

* Limiting WIP really does work. The challenge is to take that into a real setting where specialists are delivering real products.

* I’ve used other kanban simulation tools like the coin-flip game and GetKanban. This Lego Flow Game seemed to have enough complexity to make it realistic, but kept it simple enough to be able to focus on what we’re learning from the exercise.

* Identifying Lego pieces inside plastic tubs is harder than you’d think.

Overall a neat and fun exercise, to get the whole team thinking about how work flows, and how their work fits into the bigger picture of delivering a product.

Hi Joe,

Thanks for the write-up. Nicely done. Don’t worry about your Round 1 experience. No one ever delivers anything!

Karl

Thanks Karl – that’s reassuring!